Floating AutoWeir

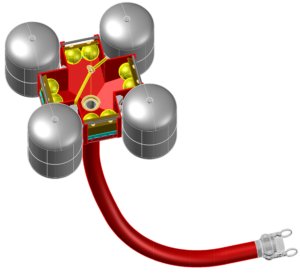

Our floating AutoWeir is an ALSI patented design to skim floating material in a recirculation tank/pit. It is placed on the top of the liquid in the tank/pit and removes paint sludge from the surface and operates based on the supply pump volume as well as the level of the liquid in the tank/pit.

The floating AutoWeir maintains the optimum skimming efficiency as operating levels change. It is equipped with several features that enhance the ability to remove contaminants without becoming clogged.