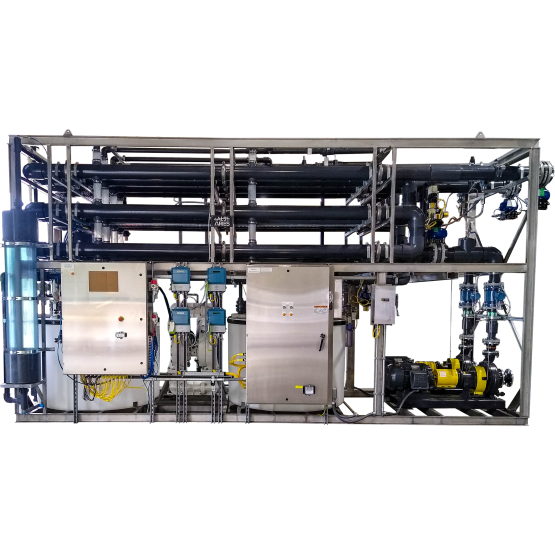

Clean-In-Place (CIP) Systems for RO Maintenance

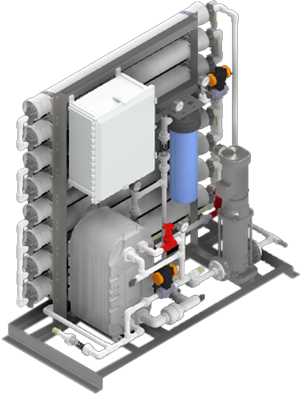

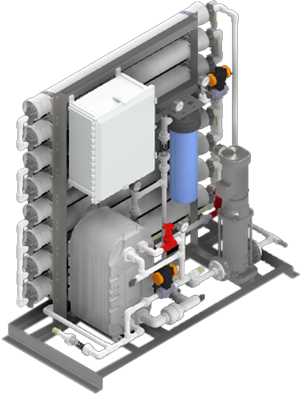

To extend membrane life and maintain peak system performance, ALSI offers CIP (Clean-In-Place) Systems designed for efficient, on-site cleaning.

Options Include:

- Integral Mounted CIP Systems: Pre-piped and pre-wired onto the RO skid with a free-standing cleaning tank.

- Skid-Mounted CIP Systems: A dedicated, portable skid for servicing multiple RO systems.

Our CIP systems efficiently manage scale buildup, biological fouling, and organic deposits, supporting long-term system efficiency.

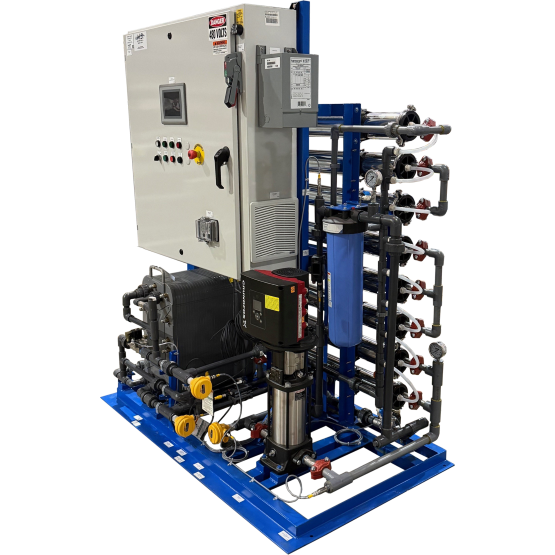

Continuous Electrodeionization (EDI) Systems for Ultra-Pure Water

For facilities requiring ultra-high purity, ALSI offers Continuous Electrodeionization (EDI) Systems—an ideal chemical-free solution for polishing RO permeate.

Key Benefits:

• Lower operational costs

• Consistent high water purity (>15 MΩ·cm resistivity)

• Environmentally friendly, safer work environment

Primary applications include electronics manufacturing, pharmaceutical production, and high-purity industrial processes.

Learn More

About EDI

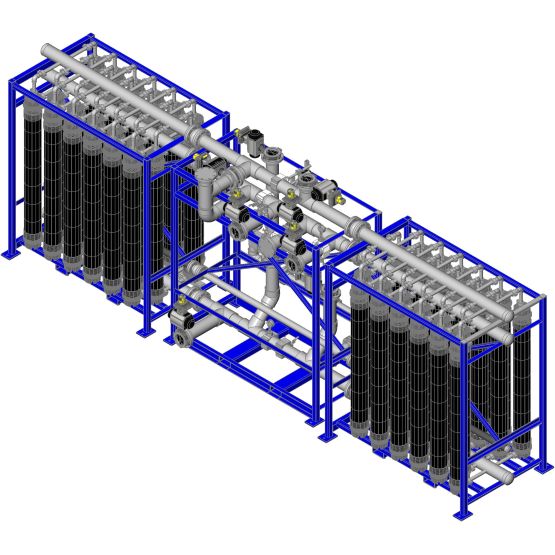

Containerized Reverse Osmosis Systems: Plug-and-Play Solutions

Our Containerized RO Systems offer a fully assembled, hydrostatically tested solution housed within standard 20- or 40-foot shipping containers—perfect for remote locations or rapid deployment needs.

Features:

- Pre-engineered and factory-tested

- Compact, space-saving design

- Quick installation with minimal site preparation

- Portable and scalable for various flow rates (25 GPM to 300 GPM)

Custom Options Available:

- VFD drives

- Chemical feed systems

- Permeate flush

- pH and ORP monitoring

- Air conditioning, man doors, and insulation