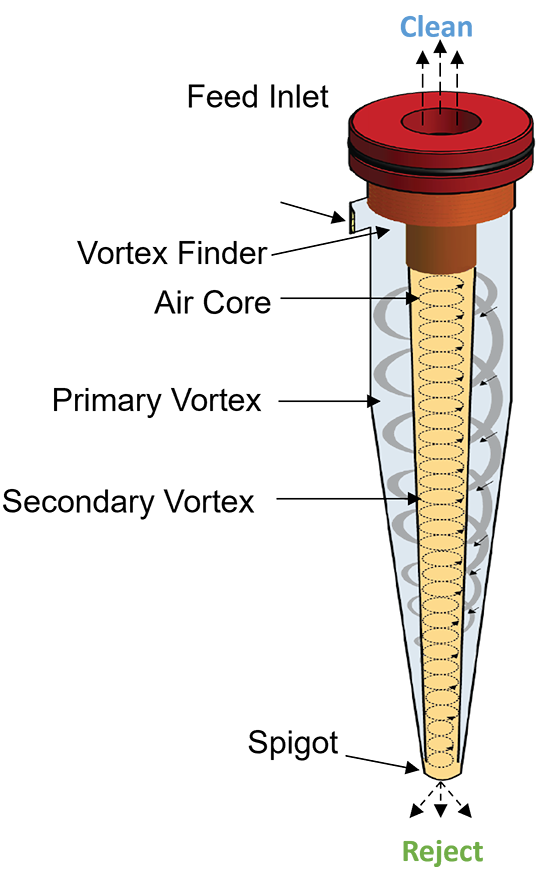

How Hydrocyclones Work

Hydrocyclones operate by leveraging the principles of centrifugal force to separate particles from fluid streams. Here’s a step-by-step breakdown of how the process works:

1. Tangential Inlet

Fluid enters the hydrocyclone tangentially at high velocity, creating a powerful circular flow pattern inside the conical chamber.

2. Vortex Formation

As the liquid spirals downward, centrifugal forces push denser particles outward toward the chamber wall while the lighter fluid moves inward toward the center.

3. Solids Discharge (Underflow)

Separated solids, now concentrated at the outer edge, spiral downward along the cone wall and are discharged through the underflow outlet at the bottom of the unit.

4. Clean Liquid Outlet (Overflow)

Meanwhile, the clarified liquid reverses direction in a tighter, inner spiral—called the vortex finder—and exits through the overflow outlet at the top.