What Is RO-Electrodeionization?

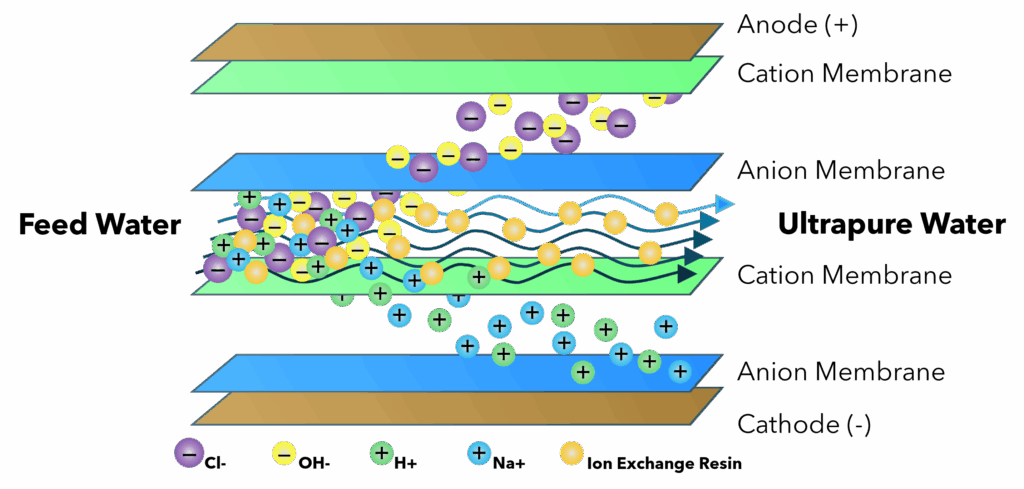

Electrodeionization (EDI), also known as Continuous Electrodeionization (CEDI), is an advanced water purification technology that continuously removes ionized and ionizable impurities from water using direct current (DC) power—without the use of chemicals.

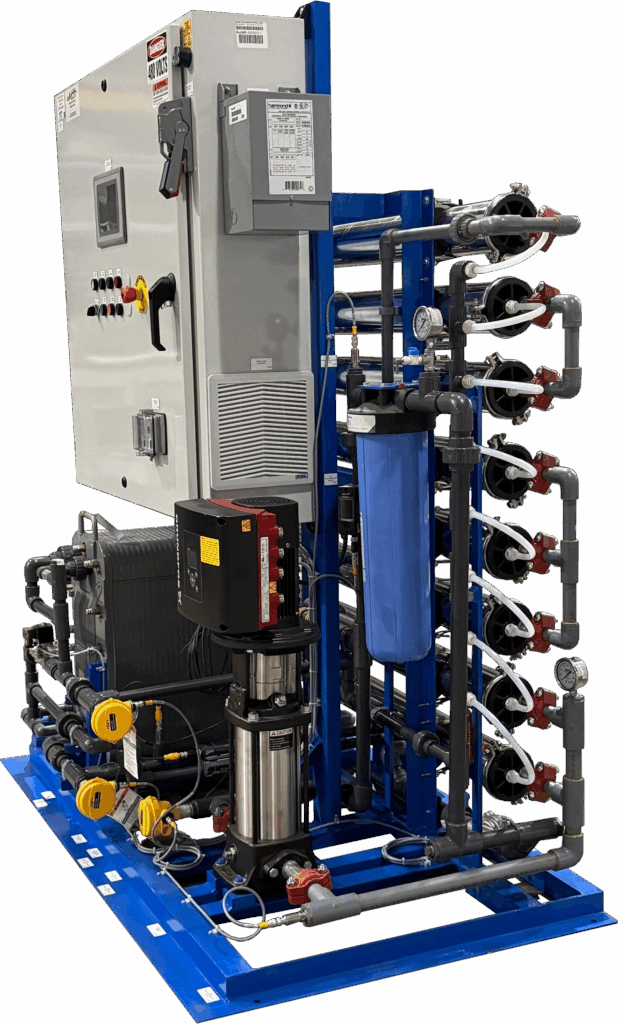

Unlike traditional mixed-bed ion exchange systems that require periodic regeneration with hazardous acids and bases, EDI is a chemical-free solution that combines ion exchange resins with electrically active membranes and a DC electrical field. This process efficiently polishes reverse osmosis (RO) permeate to deliver consistent, ultra-pure water.